Table of Contents >> Show >> Hide

- Why Sports Robots Need “Industrial Design,” Not Just Engineering

- Sports Use-Cases That Actually Fit a Robotic Arm

- Enter the Cycloidal Reducer: A Joint’s Best Friend in a Contact Sport

- Cycloidal vs Harmonic vs Planetary (Quick Reality Check)

- Performance Targets for a Sports Robotic Arm

- Designing a 3D-Printed Cycloidal Gear Stage

- Material Strategy: What to Print Cycloidal Gears With

- Lubrication: The Unsexy Feature That Saves Your Gearbox

- Safety and Human Proximity: Design Like People Will Do People Things

- Control Feel: Why Compliance Can Make Training Better

- Industrial Design Details That Make It “Sports Gear”

- Testing a 3D-Printed Cycloidal Joint Like You Mean It

- Extra Section: Real-World Experiences and Lessons Learned (500+ Words)

- Conclusion

Sports have a funny relationship with robots. On one hand, athletes want “real feel” and unpredictable chaos (because that’s the point). On the other hand, coaches love repeatabilitybecause the fastest way to improve is to practice the same motion until it becomes boring, then do it again until it becomes automatic.

That’s where sports-focused robotic arms shine: repeatable reps, controllable difficulty, and measurable feedbackwithout turning training into a science-fair project that needs a pit crew. We’re already seeing this mindset in everything from high-speed table tennis robots that track and return shots, to pro baseball pitching simulators that recreate a pitcher’s release angle and ball movement using motion and data. If you’ve ever wanted “one more perfect rep” without begging a teammate, robotics is making that wish increasingly realistic.

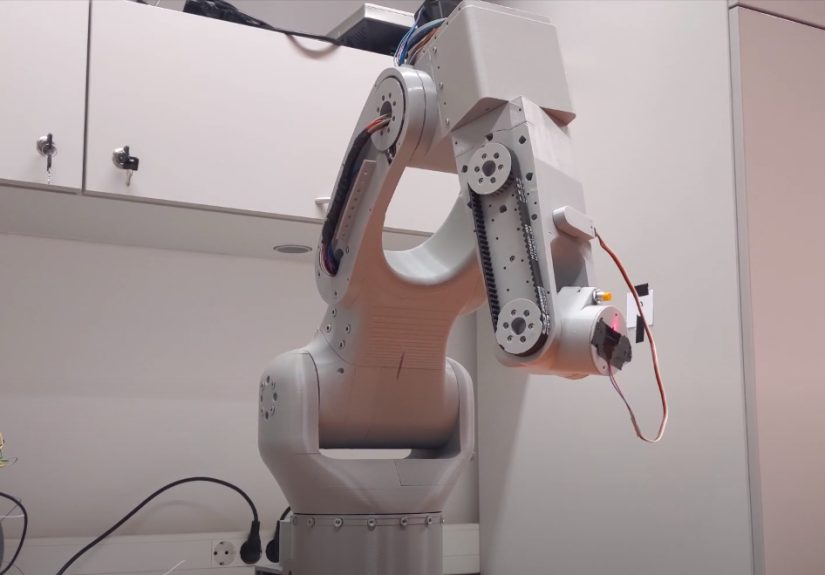

In this article, we’ll look at sports robotic arm industrial design through a practical lens: how to create a robot that’s powerful, safe, portable, and coach-friendlythen zoom in on one of the most compelling drivetrain options for joints: 3D-printed cycloidal gears (cycloidal reducers). Cycloidal drives are a favorite in robotics for compact torque, low backlash potential, and shock-load toughnesstraits that matter a lot when your robot is swinging, catching, feeding balls, or absorbing impacts like it’s part of the drill.

Why Sports Robots Need “Industrial Design,” Not Just Engineering

It’s tempting to treat a sports robot as a mechanical problem: pick motors, add reducers, slap on a gripper, done. But sports gear lives in a world of sweat, dust, turf pellets, gym bags, and people who do not read setup manuals. That’s industrial design territorywhere the goal isn’t just “it works,” but “it works for humans, fast, safely, and repeatedly.”

The sports environment is harsh in a very specific way

- Fast cycles: drills demand quick resets and reliable repetition.

- Human proximity: athletes get close, often moving unpredictably.

- Portability: training moves from cages to courts to fields (and sometimes to parking lots).

- Trust: coaches must believe it’s safe and consistent, or it becomes a very expensive coat rack.

Industrial design pushes you to treat the robot as a product: intuitive controls, clean maintenance access, safe pinch-point management, and a physical presence that feels like sports equipmentnot like a factory arm that wandered into the batting cage looking for overtime.

Sports Use-Cases That Actually Fit a Robotic Arm

Not every sports robot needs a full multi-axis arm. But when you need controlled orientation, variable trajectories, or tool swapping, an arm becomes useful. Common patterns include:

1) High-speed striking and return drills

Table tennis and similar sports demand fast reaction time, rapid repositioning, and precise paddle/face angle control. This is where low backlash, stiffness, and smooth motion show up on the scoreboard.

2) Ball feeding with realistic variation

Baseball and softball training systems increasingly blend robotics with data-driven pitch replication. Even when the “thrower” isn’t a humanoid arm, the concept is the same: repeatable mechanics, adjustable difficulty, and consistent outputs for athlete learning.

3) Handling and collection tasks

Think ball retrieval, sorting, or handing objects to an athlete during rehab or skills practice. These benefit from compliance (so the robot feels gentle) and from industrial design choices that reduce intimidation.

Enter the Cycloidal Reducer: A Joint’s Best Friend in a Contact Sport

If robotic joints were superheroes, cycloidal reducers would be the one that takes a hit, shrugs, and says, “Is that all?” Cycloidal gearing is known for distributing load across multiple contact points, which helps with shock resistance and durability under harsh conditions. That’s a big deal in sports robotics, where impact loads and abrupt direction changes are normal.

How a cycloidal drive works (plain-English version)

A cycloidal reducer typically uses an eccentric input to wobble a cycloidal disk against a ring of pins or rollers. That wobbling motion is then converted into smooth rotation at the output through pins/holes in the disk. Because many points share the load, the system can be compact yet strong.

Why cycloidal drives match sports robotics

- Shock-load tolerance: great for impacts, quick stops, and “oops” moments.

- Torque density: strong output torque in a compact envelope.

- Low backlash potential: especially with good preloading and careful clearances.

- 3D-print friendly geometry: many designs can be prototyped quickly with additive manufacturing.

Cycloidal vs Harmonic vs Planetary (Quick Reality Check)

Sports robotic arms often live in the same design space as industrial arms: they need strong joints that stay accurate under load. Harmonic drives are famous in robotics for high reduction ratios and extremely low backlash, which is why they show up in many precision arms. Cycloidal drives compete by offering shock-load robustness and stiffness advantages in many configurations.

A useful way to decide is to define the “personality” of the joint:

- Precision-first joints (fast pointing, fine placement): harmonic drives or high-quality planetary stages.

- Impact-first joints (contact tasks, abrupt reversals): cycloidal stages shine.

- Budget-first prototypes: 3D-printed cycloidal or planetary, with honest performance expectations.

In practice, many teams prototype with 3D-printed cycloidal stages, then upgrade critical joints to metal reducers if production performance requires it. The key is designing the overall arm so swapping a joint module doesn’t mean rebuilding your entire robot like it’s a reality TV home renovation.

Performance Targets for a Sports Robotic Arm

Before you touch CAD, define what “good” means in sports terms. A robotic arm doesn’t win gamesathletes do. Your job is to create a training partner that delivers consistent reps and controllable challenge.

Core metrics to define early

- Payload: tool weight (paddle, feeder, catcher, sensor rig) plus dynamic loads.

- Speed: max joint velocity and acceleration for drill tempo.

- Repeatability: can it hit the same spot/angle over and over?

- Backlash + compliance: affects “feel,” control stability, and accuracy.

- Noise: because sports facilities already have enough chaos.

- Setup time: if it takes 30 minutes to configure, it won’t be used daily.

A basic torque estimate for any joint still starts with the classic:

Tout ≈ Tmotor × ratio × efficiency.

For example, a 1 N·m motor through a 30:1 reducer at 90% efficiency yields about 27 N·m at the joint. That number is only a starting pointreal life adds inertia, impacts, friction, and safety margins.

Designing a 3D-Printed Cycloidal Gear Stage

3D printing makes cycloidal reducers feel “too accessible,” which is both exciting and dangerous. Exciting because you can iterate fast. Dangerous because it’s easy to print something that moves on the bench and then explodes into confetti under real load.

1) Geometry: the three zones that decide success

- Ring pins/rollers: contact quality here impacts friction and wear.

- Cycloid disk profile: determines smoothness, load distribution, and vibration.

- Output pin interface: where wobble becomes rotationoften a wear hotspot.

2) Clearances: small numbers, big consequences

Clearance choices affect backlash, vibration, friction, and heat. Too tight and you get binding, noise, and motor misery. Too loose and your joint feels like a shopping cart with one wobbly wheel. Research on 3D-printed cycloidal drives has specifically explored how clearance influences performance and vibration, which matches what builders see in practice: clearance is not a “minor” parameter.

3) Bearings and preloading: stiffness isn’t optional

The reducer’s job is to multiply torque. That torque has to go through bearings, shafts, and housings without turning the joint into a flexy noodle. Many high-performance reducers rely on robust output bearing arrangements and thoughtful preloading. Even in prototypes, planning for bearing stiffness pays off in accuracy and control stability.

Material Strategy: What to Print Cycloidal Gears With

Material choice is where “3D-printed cycloidal gears” either become a legit engineering solutionor a short-lived art installation titled Backlash: A Tragedy.

SLS nylon (Nylon 12 / Nylon 12 Tough)

SLS nylon is popular for functional parts because it’s tough, dimensionally consistent across the build, and can handle real prototyping loads. Nylon 12 families are often used for durable, functional prototypes and short-run end-use parts. For gear stages, SLS also helps because it avoids some of the anisotropy and layer adhesion issues that can bite FDM parts under cyclic load.

Carbon-fiber-filled nylon (e.g., “micro carbon fiber” nylon blends)

Carbon-fiber-filled nylons are known for stiffness and nice surface finish, which can help reduce “squish” in gear tooth contact and improve perceived precision. The tradeoff: they can be more abrasive and may change wear behavior depending on lubrication and mating surfaces. They’re great when you want rigid housings and stable geometry, but you still need to design for tribology (friction and wear), not just strength.

Tribology-minded plastics (self-lubricating families)

Some engineered plastics are formulated to be wear-resistant and self-lubricating, specifically to reduce or eliminate the need for external grease. That’s attractive in sports environments where dust, dirt, and maintenance time are enemies. Even if you don’t print with these exact formulations, the concept matters: design your reducer like it will be used by busy humans, not by a perfect lab tech.

Lubrication: The Unsexy Feature That Saves Your Gearbox

Gear lubrication is rarely the headline, but it’s often the difference between “works all season” and “worked for 20 minutes.” With polymer gears, lubrication can reduce friction, noise, and wearprovided it’s compatible with the plastic. Some polymer gear solutions are designed to run dry, but many 3D-printed prototypes benefit from sensible lubrication choices.

The industrial-design angle matters here too: make lubrication access simple (ports, removable covers, clear service instructions), or it won’t happen. If your maintenance process requires disassembling half the arm, congratulationsyou’ve invented a new sport called Robotics Jenga.

Safety and Human Proximity: Design Like People Will Do People Things

Sports training means people are close to the robot, moving fast, and sometimes celebrating wildly (arms flailing included). Robotics safety guidance emphasizes guarding, awareness, and hazard mitigationespecially around pinch points and unexpected motion. For sports robots, good design choices include:

- Pinch-point management: cover or shield joint gaps and moving link interfaces.

- Emergency stop placement: obvious, reachable, and not hidden like a secret level.

- Speed limits near humans: dynamic limits that reduce speed/force when people are close.

- Clear status signals: lights/sounds that indicate “armed,” “moving,” “safe,” etc.

Even if your build is “just for training,” treat safety as a design requirement, not a checklist item. It’s also part of trust: athletes and coaches will only use the system confidently if it feels safe and predictable.

Control Feel: Why Compliance Can Make Training Better

Some sports interactions benefit from a bit of complianceeither mechanical (springs, elastomers) or control-based (torque limiting, impedance control). Compliance can:

- reduce shock loads on the drivetrain (hello, longer gear life),

- make contact safer and more “natural,”

- improve robustness when athletes don’t hit the ball perfectly.

This is where concepts like series elastic actuation become relevant: adding intentional elasticity can improve force control and reduce the effect of friction and backlash on interaction tasks. For sports drills, that can mean smoother returns, safer catches, and less drivetrain abuse.

Industrial Design Details That Make It “Sports Gear”

Here’s the part many robotics projects skip: the product vibe. Sports equipment is expected to be:

cleanable, portable, intuitive, and emotionally non-threatening. (Yes, really. Nobody wants to train next to a machine that looks like it’s judging their footwork.)

Design moves that matter

- Handles and transport logic: if it’s portable, it needs real carry points and balanced weight.

- Fast mounting: quick clamps, indexed feet, repeatable setup marks.

- Touch points: textured grips where humans interact; smooth covers where they shouldn’t.

- Cable discipline: routed, strain-relieved, and protected from snags and sweat.

- Noise tuning: dampers, lubrication choices, and housings that don’t amplify gear chatter.

When these details are done well, the robot disappears into the training flowexactly what you want. The athlete should be thinking about the drill, not about whether the robot is about to do something weird.

Testing a 3D-Printed Cycloidal Joint Like You Mean It

A sports robot doesn’t fail politely. It fails during the busy week, right before the big session, when everyone is watching. Testing early prevents heartbreak later.

Practical tests that reveal the truth

- Backlash check: reverse direction under light torque and measure angular deadband.

- Heat + efficiency: run steady cycles and monitor motor current and housing temperature.

- Impact rehearsal: simulate the worst “contact” event you expect (safely), then inspect wear.

- Noise and vibration: listen for periodic “ticks” that often signal clearance or bearing issues.

- Endurance cycles: thousands of reps, because sports is a repetition business.

Builders often learn that “it turns” is not the same as “it survives.” Cycloidal reducers can be robust, but 3D-printed versions still demand realistic loads, sensible materials, and assembly accuracy.

Extra Section: Real-World Experiences and Lessons Learned (500+ Words)

You can read all the theory in the world and still get humbled by a single gritty bearing. So here are common “field experiences” reported by teams building sports-capable robotic arms with 3D-printed cycloidal gearspresented as practical lessons, not fairy tales.

Experience #1: Your first reducer will be too optimistic

Early designs often assume perfect prints and perfect alignment. In reality, printed parts have tiny dimensional drift, shafts have runout, and bearings don’t magically self-center just because you stared at them confidently. The most common first-failure pattern is subtle: the reducer feels smooth by hand, but under motor power it heats up, gets louder, and develops “crunchy” spots over time. The fix usually isn’t one big changeit’s a stack of small improvements: better bearing support, refined clearances, improved surface finish on contact areas, and a housing that doesn’t flex under load.

Experience #2: Clearance tuning is basically a sport of its own

Builders frequently end up iterating clearances like they’re tuning a race car. Too tight: binding, motor whining, and a smell that suggests your nylon is having a bad day. Too loose: backlash that makes precise drills feel sloppy, especially when direction changes are frequent (think table tennis returns or quick-feeding drills). Many teams find it helpful to print a “clearance ladder” (multiple disks or pin rings with slightly different offsets) so they can empirically choose the best compromise between smoothness and precision for their specific printer/material.

Experience #3: Housings matter as much as the gears

If the housing flexes, the reducer’s geometry changes under load. That can increase backlash, shift contact patterns, and accelerate wear. A common upgrade path is to print gears in a wear-tolerant polymer but stiffen the surrounding structure using thicker walls, ribs, or a different material strategy (for example, a stiffer composite nylon for the housing and a tougher nylon for the moving disk). In sports robotics, where impacts happen, the housing also doubles as a protective shellso it’s doing mechanical work and “product” work at the same time.

Experience #4: Lubrication and cleanliness are best friends

Sports environments are dusty. Gyms have fine grit. Fields have debris. Batting cages have everything. If you add lubricant without thinking through sealing and contamination, you can end up with an impressive grinding paste. Many builders move toward either (a) carefully chosen lubrication plus simple seals/shields, or (b) dry-running material strategies designed for low friction. The industrial-design move is making service easy: if cleaning a joint takes five minutes, it happens weekly; if it takes an hour, it happens “eventually.”

Experience #5: The best UX feature is fast setup

Coaches love tools that disappear into routine. The difference between “used every day” and “used once a month” is often setup time. Successful sports robotic arms tend to include quick alignment marks, repeatable mounting points, and a simple “ready” workflow. A great drivetrain doesn’t matter if the system feels fiddly. When teams treat setup as part of the productjust like a premium ball machine or a batting teethe robot earns a place in real training, not just in demos.

The big takeaway from these experiences is reassuring: problems are predictable, and improvements are repeatable. Cycloidal reducers are a strong option for sports robotic jointsbut they reward teams that treat printing, assembly, and human-centered design as first-class engineering disciplines.

Conclusion

A sports-focused robotic arm is a product, not a science project. That means industrial design decisionssetup time, safety, trust, serviceability, portabilitymatter just as much as torque and gear ratios. Cycloidal reducers fit this world well because they’re compact, shock-tolerant, and capable of low-backlash behavior when designed carefully. When you combine that drivetrain strategy with smart material choices, realistic clearance tuning, and a “sports gear” mindset, you get something powerful: a robot that supports athletes with consistent reps and controllable challengewithout demanding a robotics degree to turn it on.