Table of Contents >> Show >> Hide

- First: Identify Your Line-Feed Type (Because the Fix Depends on It)

- Safety Reset (Do This Before Touching Anything)

- 5-Minute Troubleshooting: The Fastest Fixes That Solve Most Line-Feed Problems

- Quick Diagnosis Table: Symptom → Likely Cause → Fix

- If You Have AFS: Fix “Automatic Feed Spool Not Feeding” the Right Way

- If You Have Bump Feed: Why It Won’t Advance Line (and How to Fix It)

- Sneaky Causes People Miss (But They Matter)

- When to Stop Troubleshooting and Get Service

- Prevent Line-Feed Problems Next Time (So This Doesn’t Become Your Weekend Hobby)

- Real-World Experiences: What Usually Fixes “My Black & Decker Weed Eater Feeding Line Is Not Working” (Extra Notes)

- Conclusion

Your Black & Decker weed eater has one main job: spin a nylon string fast enough to make weeds regret their life choices.

And yet here you arestaring at a trimmer head that refuses to feed line like it’s on strike.

The good news? Most “line won’t advance” problems come down to a handful of common causes: the wrong line, a jammed spool,

a dirty head, or a small internal part that popped out of place.

This guide walks you through a practical, step-by-step troubleshooting flow (with minimal guesswork and maximum yard-saving dignity),

whether your trimmer uses Black & Decker’s Automatic Feed Spool (AFS), bump feed, or a push-button feed.

We’ll keep it in plain American English, with clear fixes, realistic examples, and just enough humor to keep you from “accidentally”

throwing your trimmer into the neighbor’s bushes.

First: Identify Your Line-Feed Type (Because the Fix Depends on It)

Black & Decker has used a few feeding systems over the years. If you try a bump-feed trick on an AFS head, it’s like yelling at a toaster

because it won’t make coffeeenthusiastic, but not effective.

AFS (Automatic Feed Spool)

- No bumping required.

- The trimmer feeds line automatically as it senses the line getting shorter.

- Often uses a pre-wound spool (commonly labeled AF-100 on many models).

Bump Feed

- You tap (bump) the head on the ground while it’s running to advance line.

- Relies heavily on the cap, spring, and internal alignment.

Push-Button Feed

- You press a button/lever to advance line (sometimes while running, depending on design).

- Common on some newer battery models and “easy feed” styles.

Not sure which you have? Look at the head and your manual/model label. If your manual mentions AFS or “Automatic Feed Spool,” treat it as AFS.

If there’s a big bump knob designed to be tapped on the ground, it’s bump feed.

Safety Reset (Do This Before Touching Anything)

Before you open the trimmer head, cut line, or poke around in the spool housing:

- Battery models: remove the battery.

- Corded models: unplug it.

- Gas models (if applicable): shut it off and let it fully stop.

- Wear eye protection and closed-toe shoes. Trimmers throw debris like they’re paid per pebble.

5-Minute Troubleshooting: The Fastest Fixes That Solve Most Line-Feed Problems

If your Black & Decker feeding line is not working, start here. These checks solve the majority of “won’t feed” complaints without buying parts.

1) Confirm You’re Using the Correct Line and/or Spool

This is the #1 silent troublemaker. Many Black & Decker heads are designed for 0.065-inch round line.

If you use thicker line “because thicker is tougher,” you may jam the feed path. If you use thinner line, it can slip, tangle, or feed weirdly.

If your trimmer takes a pre-wound spool, use the exact compatible spool model (for many Black & Decker units, that’s commonly the AF-100 style).

Off-brand spools can work, but inconsistent winding tension and slightly different hub shapes can cause feeding issues.

2) Pop the Cap and Clean the Spool Housing

Grass clippings plus dust plus heat equals “yard cement.” That gunk can keep the spool from spinning freely or block the line from sliding forward.

Open the head, remove the spool, and clean out debris. Pay attention to:

- The inside of the cap

- The spring area

- The line exit eyelet(s)

- Any grooves where the spool seats

3) Check the Line Exit Eyelet (Where the String Leaves the Head)

The eyelet is that little “tunnel” the line passes through. If it’s packed with debris, nicked, or melted, your line can snag.

Run a small brush through it and make sure the line slides smoothly.

4) Make Sure the Cap Snaps On Fully (Yes, Really)

If the cap isn’t seated all the way, the spool can wobble. A wobbling spool feeds line like a shopping cart with one bad wheelloud, chaotic,

and not going where you want.

5) Inspect the Spring and Cap for Wear or Damage

On bump-feed heads especially, a worn cap or damaged spring can stop the feed mechanism from doing its job.

If the spring is missing, bent, or weak, the head can fail to advance line (or do the opposite and spit line out too fast).

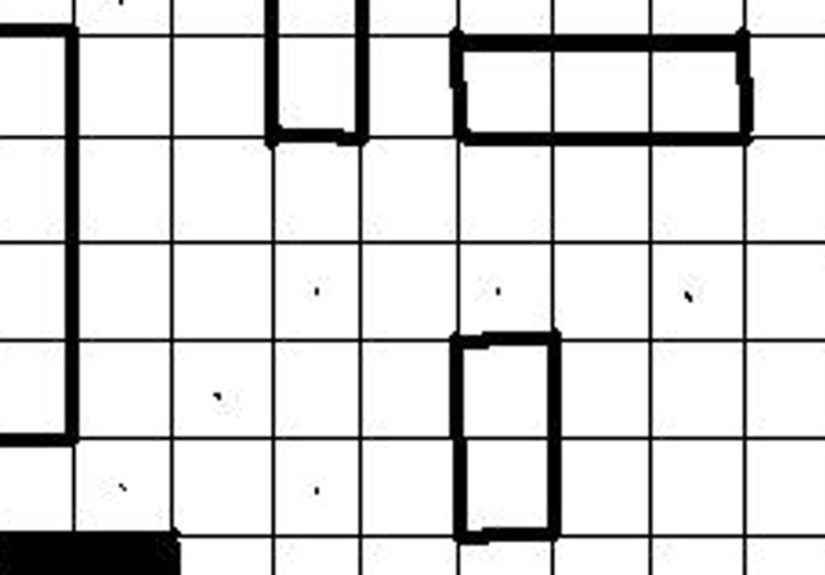

Quick Diagnosis Table: Symptom → Likely Cause → Fix

| What You Notice | Most Likely Cause | Best First Fix |

|---|---|---|

| Line won’t advance at all | Wrong line size, jammed spool, dirty head | Confirm 0.065 round line, clean head, re-seat spool |

| Line feeds but then immediately stops | Line wound wrong direction or tangled | Rewind with steady tension; don’t overfill |

| Line feeds too much / “dumps” line | Worn cap/spring, improper winding, damaged head | Inspect spring/cap; rewind neatly; check for cracks |

| Line breaks constantly | Hitting hard surfaces, brittle/old line, wrong line for job | Use tip-of-line technique; replace line; store line out of heat |

| You have to pull line out by hand | Feed mechanism not engaging or line stuck at eyelet | Clean eyelet; verify spool seating; inspect internal lever |

If You Have AFS: Fix “Automatic Feed Spool Not Feeding” the Right Way

AFS systems are designed to feed line automatically as it shortens. Translation: you generally should not need to bump the head on the ground.

In fact, repeatedly bumping an auto-advance design can cause problems for some feed mechanisms.

Step A: Install the Spool Correctly (AFS is picky, like that)

- Remove the battery/unplug the trimmer.

- Press the tabs, remove the spool cap, and pull the spool out.

- Clean dirt/grass from the spool and housing.

- Guide the line through the eyelet.

- Seat the new spool fully; rotate slightly until it sits correctly.

- Snap the cap on securely.

On many Black & Decker heads, the line should stick out a few inches after installation (and the guard blade will trim it to the correct length during use).

If line is wildly long, cut it back so it doesn’t tangle.

Step B: Check the Internal Lever (The Tiny Part That Can Ruin Your Weekend)

Some Black & Decker manuals specifically note an internal lever in the base of the housing that can become dislodged during spool changes.

If that lever is out of position, line feeding can fail even when the spool looks “fine.”

If you open the head and notice a small lever piece not sitting where it should, re-seat it according to your model’s diagram before installing the spool.

This is one of those fixes that feels too small to matteruntil it instantly solves everything.

Step C: Rewind Only If You Must (Factory Wound Often Feeds Better)

Many users like saving money by rewinding spools from bulk line. Totally fair. Just know that hand-wound spools are more likely to tangle if the line

is not wound evenly and tightly.

If you rewind:

- Use the exact diameter your head requires (commonly 0.065 round for many Black & Decker AFS units).

- Wind in the direction indicated on the spool.

- Keep steady tension. Loose wraps invite tangles.

- Don’t overfill the spool. Overfilling is basically “jam” with extra steps.

If You Have Bump Feed: Why It Won’t Advance Line (and How to Fix It)

Bump-feed trimmers are simple… until they aren’t. The bump knob/cap and spring are the main characters here.

When you bump the head, the spring compresses and the mechanism releases a bit of line.

If anything is worn, misaligned, or blocked, the line won’t advance.

1) Inspect the Spring

A damaged or missing spring can prevent proper bump action. If your spring is warped, rusted, or missing entirely,

the head may not return to position and the feed won’t work consistently.

2) Inspect the Cap / Bump Knob

If the cap is worn down, cracked, or packed with debris, it may not engage the internal mechanism.

Remove it, clean it, and check for damage. If it’s chewed up like a dog toy, it’s probably time to replace it.

3) Rewind Neatly and Don’t Overfill

Uneven winding causes overlap. Overlap causes tangles. Tangles cause the line to refuse to budge. It’s the circle of (yard) life.

Wrap the line evenly in the correct direction, and leave enough room so the line can expand slightly during operation.

Sneaky Causes People Miss (But They Matter)

The Line Is Heat-Damaged or Brittle

Trimmer line can become brittle from age, heat, or poor storageespecially if it lived through summer in a hot shed.

Brittle line breaks more easily and can create short stubs that don’t feed smoothly.

If your line snaps constantly, replace it with fresh line and store it somewhere cooler and dry.

You’re Trimming Like a Medieval Weapon

If you’re slamming the head into concrete edges, chain link fences, rocks, and tree bark, the line will break fastand feed problems can follow.

Try letting the tip of the line do the cutting work instead of forcing the head into hard surfaces.

Your trimmer will cut cleaner, waste less line, and sound less like it’s fighting for its life.

The Head or Eyelets Are Worn Out

If the trimmer head is cracked or the eyelets are worn down, the line may snag, slip, or fly out too easily.

At that point, replacing a small part (or the head assembly, depending on the model) may be more effective than endless re-spooling.

When to Stop Troubleshooting and Get Service

If you’ve verified the correct line size, installed the spool properly, cleaned the head, and checked the spring/cap/lever, but the line still won’t feed,

it may be time to contact support or a service centerespecially if:

- The head is cracked or badly worn

- The internal feed lever appears broken

- The motor surges, stalls, or the head doesn’t spin consistently

- The trimmer is under warranty and you’d rather not play “DIY roulette”

Prevent Line-Feed Problems Next Time (So This Doesn’t Become Your Weekend Hobby)

- Use the right line diameter (commonly 0.065 round on many Black & Decker headscheck your manual).

- Keep the head clean after heavy trimming, especially wet grass.

- Don’t overfill when rewinding spools.

- Wind neatly and in the right direction.

- Avoid hard impacts with concrete, rocks, and fenceslet the tip cut.

- Store line properly so it doesn’t get brittle from heat and age.

Real-World Experiences: What Usually Fixes “My Black & Decker Weed Eater Feeding Line Is Not Working” (Extra Notes)

If you’re reading this section, you’re probably past the “simple fix” stageand emotionally invested.

So here are the most common real-life scenarios people run into with Black & Decker trimmers, plus what tends to actually solve them.

Think of this as the “support group” portion of the article, minus the folding chairs.

Experience #1: The “I Bought Stronger Line” Backfire.

A lot of homeowners grab thicker line because it sounds logical: thicker line should last longer, right?

In practice, many Black & Decker heads are designed around a specific diameter (often 0.065 round).

When thicker line gets shoved into that system, it doesn’t glide through the eyelet smoothly, the spool can bind,

and the feed mechanism can’t do its job. The fix ends up being hilariously simple: switch back to the recommended size,

clean the head, and suddenly the trimmer feeds like it remembered its purpose in life.

Experience #2: The “It Fed Fine Until I Replaced the Spool” Mystery.

This one is extremely common. The trimmer feeds perfectly… until the first spool change.

What happened? Usually one of three things:

(1) the cap didn’t snap on completely,

(2) the line wasn’t routed cleanly through the eyelet,

or (3) a small internal piece (like a lever in the housing) got knocked out of position while swapping spools.

People often re-do the same spool install three times and swear the trimmer is cursed.

Then they re-seat the spool, rotate it slightly until it fully seats, and snap the cap on firmlyproblem solved in 30 seconds.

Experience #3: The “Wet Grass Glue” Situation.

Trimming damp grass can pack the head with a paste-like mess that dries into a gritty plug.

The spool may still spin, but the line can’t slide forward freely, so it looks like the feed “stopped working.”

A quick clean-out (and making sure the eyelet isn’t jammed) fixes it. The lesson: the trimmer head needs occasional cleaning,

especially after going through thick or wet growth.

Experience #4: The “It Keeps Dumping Line Like It’s Celebrating” Problem.

Sometimes the problem isn’t that line won’t feedit’s that it feeds way too much.

That often points to a worn cap, a tired spring, or sloppy winding that lets the line pop loose.

People typically notice it most when edging along a sidewalk: line shoots out, gets cut by the guard blade, and disappears at cartoon speed.

The fix is usually inspecting the spring and cap for wear, then rewinding with tight, even wraps (or switching back to a factory-wound spool).

Experience #5: The “I Thought It Was Bump Feed” Oops.

This is the quiet villain of frustration: some users keep bumping an AFS-style head because that’s what they’ve always done with other trimmers.

But AFS systems are designed to feed automatically as the line shortens. When you stop treating it like a bump-feed head,

run it normally, and let the guard blade trim the line to the right length, it often starts behaving.

In other words: your trimmer might not be brokenit might just be misunderstood.

If any of these experiences sound painfully familiar, don’t worryyou’re not alone.

Most feeding problems are fixable with the right line size, a clean head, and a correctly seated spool.

And if not? At least you’ll know you tried the smart fixes before resorting to dramatic interpretive dance in the driveway.

Conclusion

When your Black & Decker weed eater feeding line is not working, it usually comes down to a few repeat offenders:

incorrect line diameter, tangled or overfilled spools, debris-packed housings, worn caps/springs, or a small internal lever out of position.

Start with the quick checks, confirm your feed type (AFS vs bump vs button), and install the spool carefully.

In many cases, the “repair” is really just a clean-out and a correct reloadno fancy tools, no expensive parts, and no new trimmer required.