Table of Contents >> Show >> Hide

- Why the C-5 Is a Surprisingly Good “Hospital Canvas”

- What “Flying Hospital” Really Means (and What It Doesn’t)

- The Air Force’s C-5 “Flying Hospital” Concept: Big Capacity, Worst-Day Readiness

- Proof-of-Concept Flights: Turning a Cargo Bay into a Care Bay

- The Patient Math: Capacity Is More Than a Number

- Why This Matters Beyond Combat: Disasters, Evacuations, and “Hospital-Scale” Moves

- How CCATT Turns Cargo Aircraft into Flying ICUs

- What About Infectious Disease Moves?

- The Hard Parts: Certification, Safety, and Reality at 30,000 Feet

- So… Will the C-5 Really Become a Flying Hospital?

- Experiences From the “Flying Hospital” World (An Extra )

- Conclusion

If you’ve ever walked into the belly of a C-5M Super Galaxy, you know the first thought isn’t

“airplane.” It’s “warehouse.” Or “indoor soccer field.” Or “this could fit my entire to-do list and still have room

for a forklift.” That oversized reality is exactly why the U.S. Air Force has explored a bold idea:

turning the C-5 into a flying hospitalnot in the TV-drama sense of surgeons doing slow-motion

high-fives over an operating table mid-turbulence, but in the very real, very urgent sense of moving

large numbers of patients quickly with serious medical capability onboard.

The concept is simple to say and hard to execute: take the Air Force’s largest cargo aircraft, use its cavernous

interior and upgraded power systems, and configure it for mass aeromedical evacuation.

In a world where disasters can overwhelm local hospitals overnight and conflicts can produce large patient surges,

the appeal is obvious. One aircraft. One mission. A whole lot of people moved from “in danger” to “getting care.”

Why the C-5 Is a Surprisingly Good “Hospital Canvas”

The C-5 Galaxy was born to move big, awkward thingstanks, helicopters, oversized equipmentacross huge distances.

That design DNA comes with three traits that make medical planners look at it and think, “Okay… what if?”

1) Space that behaves like real estate

Aeromedical evacuation (AE) is partly medicine and partly geometry. You need room for patients, caregivers,

equipment, oxygen, and safe movement in tight quarters. The C-5’s cargo compartment gives planners something

they rarely get on aircraft: options. You can lay out patient “lanes,” create treatment zones,

stage supplies, and still preserve working space for medics who must do delicate tasks while everything vibrates,

hums, and occasionally reminds you that gravity is a suggestion at 30,000 feet.

2) Electrical power that modern medicine demands

Today’s en-route care is not just bandages and bravery. It’s monitors, ventilators, suction, infusion pumps,

portable lab tools, warming devices, and communications gear. As the C-5 fleet was upgraded to the

C-5M configuration, it gained modern systems that help support power-hungry medical equipment.

In other words: the aircraft can do more than move bodies; it can help keep patients stable while they move.

3) Long-range airlift that can connect to higher levels of care

A flying hospital only matters if it can connect patients to definitive care. Strategic lift aircraft shine here:

they can bridge long distances quickly, moving patients from austere or overwhelmed regions to places that can

treat themwhether that’s a major hub hospital, a military treatment facility, or a region with surge capacity.

What “Flying Hospital” Really Means (and What It Doesn’t)

Let’s clear the airpreferably through a HEPA filter. When defense writers say “flying hospital,” it’s easy to

picture a fully staffed trauma center in the sky. That’s not the practical goal. The realistic target is

high-capability transport care: stabilizing, monitoring, and treating patients during flight so

they can safely reach more advanced care.

The Air Force already does this through a mature aeromedical evacuation system. Think of it as a coordinated chain:

patient movement planning, trained AE crews, equipment packages, aircraft configurations, andwhen patients are

especially fragilespecialized critical care teams.

The core building blocks of Air Force aeromedical evacuation

-

Aeromedical Evacuation (AE) crews trained to provide en-route care and configure aircraft with

litter systems, oxygen, and medical gear. -

Patient movement items and standardized equipment kits that can be staged, loaded, and tracked

across missions and theaters. -

Critical Care Air Transport Teams (CCATT)three-person teams that can essentially bring ICU-level

capability onboard cargo aircraft for the most complex patients.

In short: the “hospital” isn’t a single object rolled up the ramp. It’s a systemand the C-5 is being

evaluated as a platform that could dramatically increase how much of that system can move in one trip.

The Air Force’s C-5 “Flying Hospital” Concept: Big Capacity, Worst-Day Readiness

The strategic question behind the C-5 medical concept is brutally practical:

What’s the best option on the worst day?

Smaller aircraft can do smaller missions well. The Air Force already uses platforms like the C-130 and C-17 for

aeromedical evacuation, and those aircraft are workhorses for both combat and humanitarian operations. But if you

suddenly need to move an entire hospital’s worth of patientsor evacuate a region where hospitals are

compromisedcapacity becomes the limiting factor.

That’s where the C-5 turns from “big plane” into “strategic capability.” In evaluations discussed publicly,

Air Mobility Command explored whether a C-5M could carry more than 100 patientsa potential surge

capacity leap compared to existing single-aircraft AE loads. The goal isn’t to replace other platforms; it’s to

add a “mass move” option when the scenario is too large for the normal playbook.

Proof-of-Concept Flights: Turning a Cargo Bay into a Care Bay

You don’t certify a flying ICU with PowerPoint and positive vibes. You test itcarefully, repeatedly, and with the

people who will actually do the work.

The Air Force conducted proof-of-concept efforts in late 2018 that brought together “total force” teamsactive,

Guard, Reserve, and command expertsto evaluate the C-5M as an AE platform. The work focused on using the

cargo compartment for patient care, not just the smaller passenger areas historically used on some

flights.

Two key lessons emerged from public descriptions of those early tests:

-

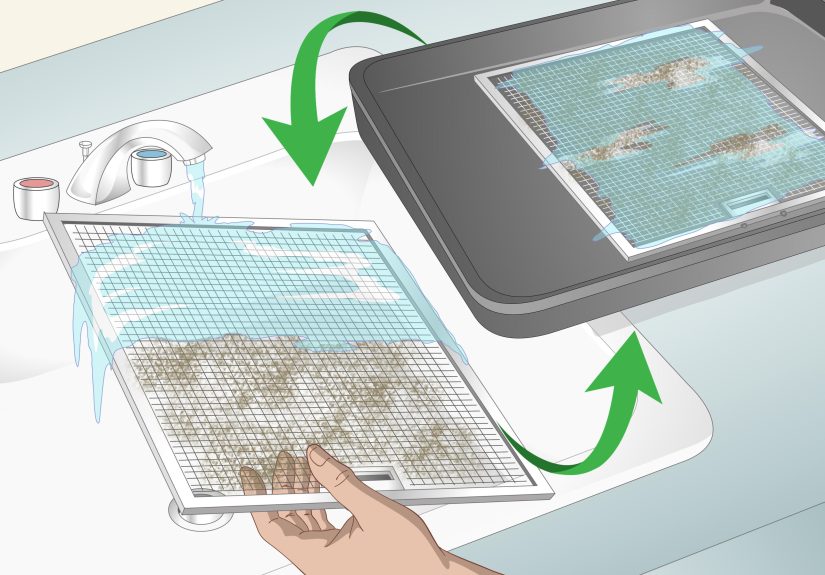

The C-5M upgrades mattered. More electrical capacity and improved environmental control made the

cargo bay more viable for patient care. -

Standardization matters even more. If the C-5 is going to be a dependable AE option, crews need

repeatable configuration guidancewhere litters go, how oxygen is routed, how equipment is staged, and how teams

move safely during flight operations.

That second point is easy to underestimate. In aeromedical evacuation, the setup is part of the medicine.

The difference between “we can carry patients” and “we can carry patients safely, repeatedly, and at scale” is

training, checklists, certification standards, and a whole lot of details you only learn by doing.

The Patient Math: Capacity Is More Than a Number

You’ll see headlines about “100+ patients,” and that’s the attention-grabber. But real-world aeromedical planning

depends on constraints that don’t fit neatly into a single number.

Staffing: the invisible ceiling

More patients require more caregiversor at least a design that lets a limited number of medics safely monitor and

treat many people at once. Some patients may be ambulatory; some may be litter patients; some may need critical

care. The staffing model changes everything: how many CCATT teams you need, how many AE crew members, and how much

care can realistically be delivered during long legs.

Oxygen: the quiet kingmaker

Oxygen planning is one of those topics that sounds boring until you realize it’s the difference between “mission”

and “medical emergency.” Aeromedical crews plan oxygen consumption based on patient needs, flight duration, and

equipment demands. When you scale up the number of patients, oxygen becomes a mission-critical resource on par with

fuel and runway length.

Power, placement, and access

Litter placement isn’t random. Crews think about vibration, temperature differences in the cargo bay, accessibility

during turbulence, and the ability to respond if a patient deteriorates. If you’re transporting high-acuity

patients, you want quick access to airways, lines, monitors, and medicationswithout climbing over other patients

like it’s an obstacle course designed by a mischievous gym teacher.

In short: the C-5’s size gives you capacity, but the system still has to produce care. The plan

only works if the aircraft can be configured in a way that supports safe workflows.

Why This Matters Beyond Combat: Disasters, Evacuations, and “Hospital-Scale” Moves

One reason the “C-5 flying hospital” idea keeps resurfacing is that mass-casualty situations are not exclusive to

combat. Hurricanes, earthquakes, wildfires, and infrastructure failures can all create conditions where local care

capacity collapses.

Public comments tied the concept to real disasters and near-miss scenariosevents where moving large numbers of

patients quickly could save lives or prevent a collapsing health system from turning bad outcomes into worse ones.

In a major hurricane scenario, for example, a large airlifter could potentially:

- Fly in water purification gear, shelters, blankets, and medical support supplies.

- Stage the response at an airfield serving as a logistics hub.

- Then “flip the load” and fly out high-need patients to safer, higher-capacity facilities.

That “two-way value” is part of the pitch: the plane isn’t only an evacuation tool. It’s also a massive delivery

vehicle for relief suppliesmaking it useful even before the first patient is loaded.

How CCATT Turns Cargo Aircraft into Flying ICUs

If the phrase “flying hospital” has a beating heart, it’s the Critical Care Air Transport Team.

CCATT teams are designed to extend intensive care into the air mobility system, enabling the transport of

critically ill and injured patients who can’t ride in a “standard” configuration without significant risk.

The Air Force describes CCATT as a capability that helps move service members from injury to stateside care in

less than three days, a dramatic shift compared to historical evacuation timelines. The teams are

trained for complex casesburns, shock, respiratory failure, multisystem traumaand they bring equipment that can

support ICU-level monitoring and intervention during flight.

This matters for the C-5 concept because it reframes the aircraft’s role. The C-5 isn’t expected to be a floating

hospital building; it’s expected to be a platform that can carry the right teams and tools at

scaleespecially when the patient surge includes people who are unstable, ventilated, or otherwise high-acuity.

What About Infectious Disease Moves?

Modern patient movement has to account for something older than aviation: contagion. The Air Force has developed

isolation capabilities for high-consequence infectious diseases, including palletized systems designed to protect

aircrew and medical attendants while still enabling in-flight care.

One example publicly described is the Transport Isolation System (TIS), which uses pallet-mounted

modules and HEPA filtration to contain pathogens. TIS was driven by an operational need identified during the

2014 Ebola response, passed “Safe to Fly” testing later that year, and was accepted as an initial capability in

early 2015.

While TIS is associated with specific aircraft compatibility in official descriptions, the larger point for the

“flying hospital” conversation is this: large-scale evacuation planning now includes scenarios where you can’t

simply line up patients and go. You may need containment, controlled workflows, and deliberate aircraft

configurationespecially if the crisis involves infectious disease.

The Hard Parts: Certification, Safety, and Reality at 30,000 Feet

Turning a cargo aircraft into a care environment is possible. Turning it into a certified, repeatable,

safe, and scalable capability is the hard part. Here are the big hurdles that tend to dominate real-world planning:

Aircraft certification and configuration control

Medical equipment has to be secured. Loads must meet airworthiness standards. Electrical demand must stay within

limits. Oxygen systems must be integrated safely. Patient litter systems must be anchored correctly. Every one of

those items requires testing and standardized proceduresbecause “it worked once” is not the same as “it works

every time.”

Environmental control (and the human factor)

Cargo bays are not designed to be cozy. Temperature gradients, noise, vibration, and limited lighting complicate

care. When you scale to large numbers of patients, comfort becomes a safety issue: patients can get colder, sicker,

more anxious, and harder to manage. Medics also fatigue faster in harsh conditionsespecially on long missions.

Workflow under constraints

In-flight care means doing medical tasks in narrow aisles, with limited ability to hear, limited ability to use a

stethoscope, and limited ability to move quickly during turbulence or tactical procedures. That’s true on any AE

aircraft. On a C-5 configured for mass movement, it becomes a choreography challenge: you need lanes, staging

points, and clear roles so that “help the sickest patient” doesn’t turn into “trip over the supply pile.”

So… Will the C-5 Really Become a Flying Hospital?

The most honest answer is that the C-5 concept is best understood as a surge optiona way to add a

“mass evacuation” lever to the Air Force’s existing AE toolkit. The service already has proven aeromedical

evacuation platforms. The C-5’s value proposition is scale: when the situation is too large for routine capacity,

it could help move more patients in fewer sorties.

Whether that becomes a routinely tasked capability depends on certification, training pipelines, and operational

demand. But the idea itself is consistent with how the Air Force thinks about readiness: you don’t build for the

average day. You build for the day you hope never comes.

Experiences From the “Flying Hospital” World (An Extra )

To understand why the “C-5 flying hospital” idea is both exciting and intimidating, it helps to picture what

aeromedical evacuation feels like in practicebecause the aircraft isn’t just a platform. It’s an

environment that shapes care.

It often starts with math and a briefing. Before a mission, AE teams review how many patients they’ll carry, what

conditions those patients have, and what could go wrong. Oxygen planning becomes its own mini-discipline:

how much each patient will need, how long the flight will be, and what equipment will draw oxygen or power. The

lead flight nurse assigns responsibilities and game-plans worst-case scenarios: a patient decompensates, a device

fails, the aircraft diverts, or the cabin environment becomes harder to manage than expected.

Then comes the physical build-out. Cargo aircraft don’t come pre-decorated like an ambulance. Crews install vertical

stanchions to support litters, run oxygen and electrical lines, and create a layout that can be maintained even

after takeoff when movement is restricted. Placement decisions can be surprisingly nuanced: some parts of an

aircraft vibrate more, some areas run colder, and some spots give better access for treatment. Even “simple” care

changes when you’re working in a metal tube with limited space and constant motion.

Once airborne, the sensory reality kicks in. Noise is the first thing people mentioncargo aircraft are loud enough

that normal conversation becomes a mime show with hand signals and head nods. Lighting can be limited for safety,

especially in tactical settings, which means medics may use headlamps and work in small pools of colored light.

Vibration is constant; you learn quickly that fine motor taskstaping lines, adjusting tubing, reading monitors

take more time and more patience than they would in a calm hospital room.

Now scale that to the C-5 concept. Imagine a cavernous cargo bay set up for mass movement: multiple rows of patients,

equipment staged like a mobile supply room, and medics moving with purpose down clear lanes. In a best-case mission,

many patients are stable, ambulatory, and simply need transport. In a tougher mission, a subset may require CCATT

supportpatients needing ventilation, careful sedation management, or continuous monitoring. The C-5’s promise is

that, with the right configuration and the right teams, you can treat the aircraft like a moving clinical space:

not a full hospital, but a high-capability bridge between danger and definitive care.

The most striking “experience” theme from aeromedical crews is that success often looks quiet. No dramatic music.

No heroic monologues. Just checklists, teamwork, and the steady rhythm of people doing hard work in a hard place.

When a mission goes well, the aircraft lands and patients are handed off in better shape than they would have been

without that flying bridge. And in the context of mass evacuation, that can be the difference between a crisis that

overwhelms a regionand a crisis that, while still awful, stays survivable.

Conclusion

The idea of turning the C-5 Galaxy into a flying hospital is less about novelty and more about

readiness. The Air Force already operates a robust aeromedical evacuation system, complete with specialized

critical care teams that can bring ICU-level capability into the airlift fleet. What the C-5 adds is scale:

the potential to move a hospital-sized patient load when disasters or conflict create an urgent surge.

If the C-5M becomes a certified, standardized AE platform, it won’t replace existing aeromedical aircraftit will

complement them as the “big answer” for the biggest scenarios. And while “flying hospital” makes a great headline,

the real story is more impressive: a carefully tested, system-driven capability designed to move people faster,

farther, and more safely when time matters most.